Upgrade Your Devices With Reliable and resilient Birthing Bushings

When it comes to updating equipment, one frequently neglected yet vital aspect is the top quality of bearing bushings. Spending in durable and trusted bearing bushings can make a globe of difference in terms of efficiency, long life, and total cost-effectiveness. In this conversation, we will discover the solutions to these inquiries, providing beneficial understandings right into the world of bearing bushings and exactly how they can enhance your devices's capacities.

Significance of Upgrading Bearing Bushings

Updating bearing bushings is vital for maintaining optimal tools performance and longevity. Bearing bushings play a crucial function in decreasing rubbing and ensuring smooth rotational motion in numerous kinds of equipment, such as industrial equipment, auto elements, and even household appliances. With time, these bushings can wear out due to long term usage, high temperature levels, or direct exposure to extreme operating problems. When the bushings wear out, the tools's performance can be endangered, bring about enhanced power usage, reduced effectiveness, and potential break downs.

Upgrading bearing bushings offers a number of benefits. By replacing damaged bushings with better and brand-new ones, devices operators can make sure smooth and reliable operation, resulting in boosted productivity and price savings.

Additionally, updating bearing bushings offers a chance to boost equipment performance. More recent bushings usually feature improved lubrication residential properties, minimizing the requirement for frequent lubrication and ensuring optimum efficiency popular applications. Updated bushings can likewise supply better load-bearing capacities, permitting tools to take care of much heavier loads and operate under more tough conditions. This can be specifically beneficial in markets such as construction, production, and mining, where tools is subjected to hefty usage and extreme operating conditions.

Trick Advantages of Resilient Bearing Bushings

With the value of updating bearing bushings established, it is vital to recognize the key advantages that resilient bearing bushings supply. Durable bearing bushings offer numerous advantages that contribute to the general efficiency and durability of equipment.

Durable bearing bushings are made to endure heavy tons, high rates, and rough operating problems without compromising performance. By making sure efficient and smooth procedure, these bushings aid improve the general dependability of the devices.

Long lasting bearing bushings are made from premium materials that supply outstanding strength and durability. With their exceptional longevity, these bushings can endure frequent use and expanded service life, lowering the need for frequent substitutes.

Additionally, long lasting bearing bushings contribute to enhanced performance. By decreasing friction and decreasing energy loss, they assist maximize the performance of turning equipment. This brings about lower energy usage, boosted productivity, and minimized operating expenses. The improved effectiveness likewise converts into smoother operation, reduced vibration, and minimized noise degrees.

Factors to Take Into Consideration When Picking Trustworthy Bushings

When selecting dependable bushings, it is necessary to meticulously take into consideration numerous factors to make sure ideal efficiency and durability of the devices. One of the most crucial variables is the product utilized in the building and construction of the bushing. Various products have varying levels of sturdiness, resistance to use, and capability to deal with particular conditions such as heats or harsh atmospheres. It is important to pick a material that is ideal for the particular application and can hold up against the needs of the tools.

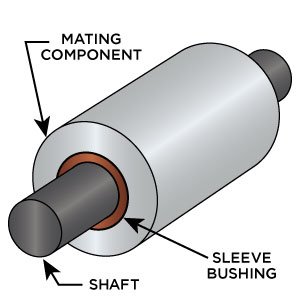

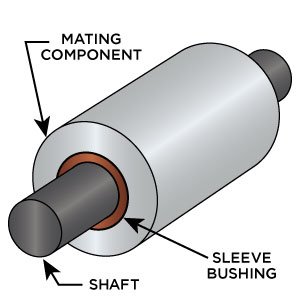

Another variable to think about is the design and dimension of the bushing. The design should work with the devices and permit smooth procedure and very little rubbing (bronze bushing). It is additionally essential to pick the right size to ensure a correct fit and avoid any kind of unnecessary anxiety or strain on the bushing

Furthermore, the load ability of the bushing need to be taken into account. This describes the maximum tons that the bushing can deal with without experiencing failure or deformation. It is crucial to select a bushing with a load capacity that matches or goes beyond the requirements of the equipment.

Finally, thinking about the upkeep requirements and accessibility of substitute bushings is essential. It is vital to select bushings that are easy to preserve and change if required, to reduce downtime and ensure continual operation of the equipment.

Installment Tips for Updating Devices With Bushings

Taking into consideration the different factors associated with choosing trustworthy bushings, it is crucial to now focus on the installment suggestions for updating devices with these necessary parts.

Correct installation of bushings is essential to ensure optimal efficiency and durability of the updated equipment. Right here are some crucial pointers to bear in mind:

- Clean and examine: Prior to setting up the new bushings, extensively tidy the equipment's mating surface areas and guarantee they are free from debris or old bushing remnants. Examine the mating surfaces for any type of signs of damages or wear that may affect the performance of the brand-new bushings.

- Lubrication: Apply a thin layer of lubricating substance compatible with the bushing material to the mating surfaces. This will certainly decrease rubbing throughout installation and guarantee smooth operation of the bushings.

Correct fit: Ensure the bushings have the right dimensions and tolerances for the equipment. Usage suitable devices, such as press-fit devices or hammers, to attain a snug fit without harming the bushings or equipment.

- Alignment: Line up the bushings effectively with the mating surfaces to guarantee smooth motion and prevent binding or misalignment. Use positioning tools or strategies, such as dial indications or laser positioning systems, if required.

- Look for correct performance: After installment, examine the tools to ensure that the bushings are working properly. Try to find any type of indications of irregular wear, sound, or extreme heat, which may indicate a misalignment or other problems.

Maintenance and Look After Durable Bearing Bushings

To guarantee the longevity and optimal performance of birthing bushings, it is vital to execute appropriate maintenance and care practices. Normal upkeep is vital recommended you read to avoid early wear and tear, decrease the threat of failing, and extend the life expectancy of the bushings. Among the primary maintenance tasks is lubrication. Correct lubrication makes certain smooth and smooth operation, decreasing the chances of damage and boosting general performance. It is essential to make use of the proper lubricating substance suggested by the manufacturer and use it at normal periods. Evaluations need to additionally be carried out periodically to examine for any type of signs of rust, damages, or wear. This includes examining the bushings for any type of abnormal sound, excessive play, or getting too hot. If any type of issues are detected, prompt activity ought to be required to resolve them, such as replacing broken or worn-out bushings. Furthermore, maintaining the surrounding atmosphere clean and cost-free from contaminants is critical in preserving the performance and long life of the bushings. Normal cleaning and eliminating any debris or dust buildup can stop damages and ensure smooth operation. By applying these maintenance and care methods, tools owners can make best use of the lifespan of their bearing bushings, lessen downtime, and attain optimal performance.

Conclusion

In final thought, upgrading tools with trustworthy and resilient bearing bushings is crucial for optimum performance and long life. Eventually, investing in high-grade bushings will result in improved devices efficiency and lowered downtime.

Bearing bushings play a crucial duty in official statement minimizing friction and making sure smooth rotational movement in numerous types of equipment, such as commercial machinery, auto elements, and also home devices. By replacing worn-out bushings with brand-new and enhanced ones, devices drivers can guarantee smooth and reliable operation, resulting in boosted productivity and expense financial savings. By making sure smooth and efficient procedure, these bushings aid improve the general integrity of the equipment.

When choosing reliable bushings, it is necessary to thoroughly consider a number of variables to make certain optimum performance and durability of the devices. Tidy and inspect: Before setting up the brand-new bushings, extensively his comment is here tidy the tools's mating surfaces and guarantee they are cost-free from particles or old bushing residues.